Our Strengths【2-1】technology

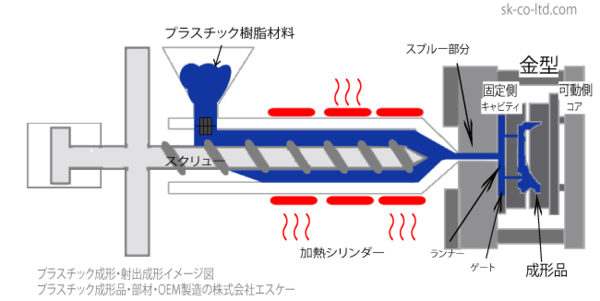

silicone molding/injection molding/die casting

We will create New Value to the client’s future by strong technical force rich production experience.

we will determine whether to perform rubber or plastic resin molding in Japan or overseas according to the various needs of our customers, such as the difficulty of the product, the quantity to be produced, and the budget, and make the best proposal.

| Rubber molding technology / metal processing [2D / 3D data conversion, shortest delivery time, lowest price] |

| Compression molding (press molding), injection molding (transfer) molding, injection molding Injection molding, LIM molding (liquid resin injection molding), casting molding, lathe processing, cutting integration processing, Water jet cutting, cutting plotter processing, compound processing, integral molding etc. |

| Plastic molding technology / metal working [2D / 3D data conversion, shortest delivery time, lowest price] |

| ・ Injection molding ・ LIM molding ・ Blow molding ・ Calendar molding (polyvinyl chloride) ・ Machining (NC slice) ・ Cutting (turning) ・ Vacuum, pressure molding (container / tray) ・ Inflation molding (film / bag) ・ Compression molding (various to heat-curing resin) ・ FRP molding-tank / ship- (hand lay-up molding / spray-up molding) ・ integral molding (insert molding) ・ molding by 3D printer |